Atmos Nano Exhaust System

The Atmos Nano exhaust system is the ultra compact choice for fiber laser marking applications. It has a small footprint and fits neatly beneath a workstation.

Trotec lasers for marking, engraving and cutting are supplied in such a configuration that they can be used immediately – of course after installation by our technicians and initial training in operation and maintenance. In addition to standard accessories such as a laser pointer, metal table or JobControl software, it is suitable for some applications, to increase productivity or for greater operator comfort, to supplement the laser with optional accessories.

The Atmos Nano exhaust system is the ultra compact choice for fiber laser marking applications. It has a small footprint and fits neatly beneath a workstation.

Continuous improvement has led to the development of the latest system in the Atmos portfolio. The Atmos Cube replaces the

The extraction device Trotec Atmos Pure 300 is designed for Trotec lasers. The extraction activity is monitored and the operator

The interaction between Ruby and Speedy Run On Ruby increases the quality of the engraving. Thanks to HDLR – High

The extraction device Trotec Atmos Pure 600 is equipped with two turbines and is intended for Trotec Speedy 360, Speedy

The Trotec Vent series has been designed as a simple extraction system for specific configurations of laser machines. They guarantee

Prefilters: Pre-separators for high-dust laser engraving and cutting applications Trotec offers an exhaust system specially designed for engraving or cutting

The mechanical pre-filter for the laser is especially suitable for manufacturers of stamping plates. A passive device with a high degree of filtration is connected between the laser and the extractor and its task is to capture as much dust as possible and thus extend the life of the main mechanical filter in the extractor.

During laser marking (especially marking in plastics, rubber, …) often arise fumes which have to be sucked and filtered. The

Trotec Ruby is a new software platform and provides a new user interface. Use the integrated workflow to create graphics,

Innovative laser software that offers maximum operator comfort for preparing your laser jobs. Laser engraving and laser cutting will be as easy as child’s play.

Rayjet Manager is based on Trotec’s industry-leading software concept. With Rayjet Manager software and Rayjet Commander printer driver, files are

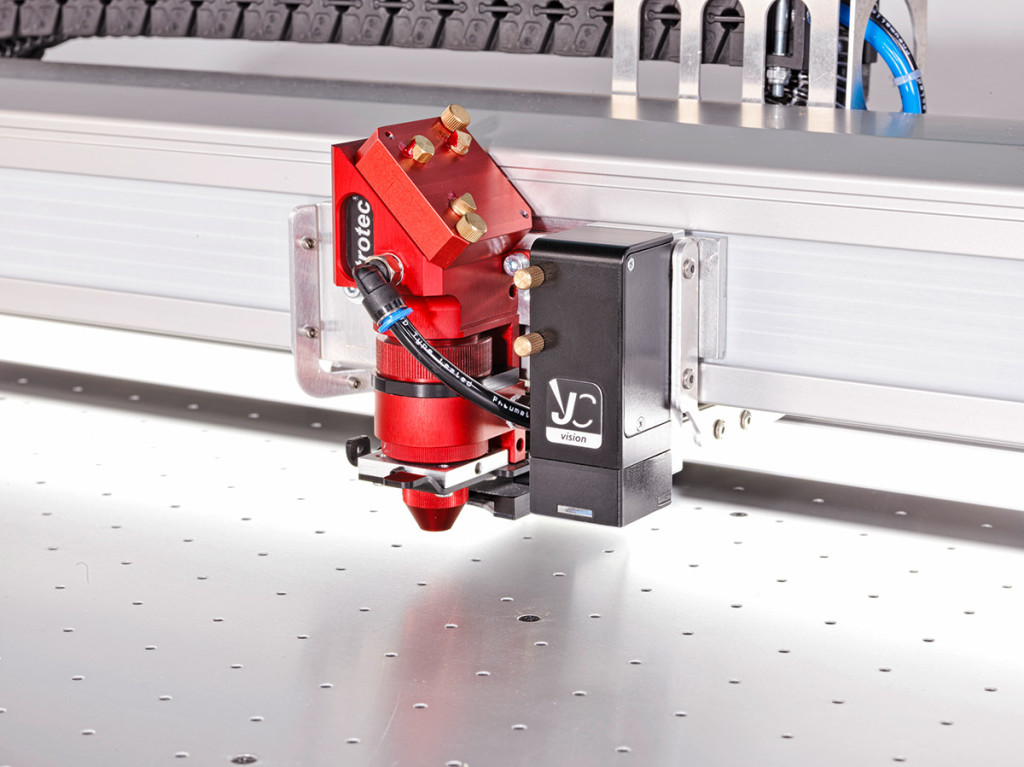

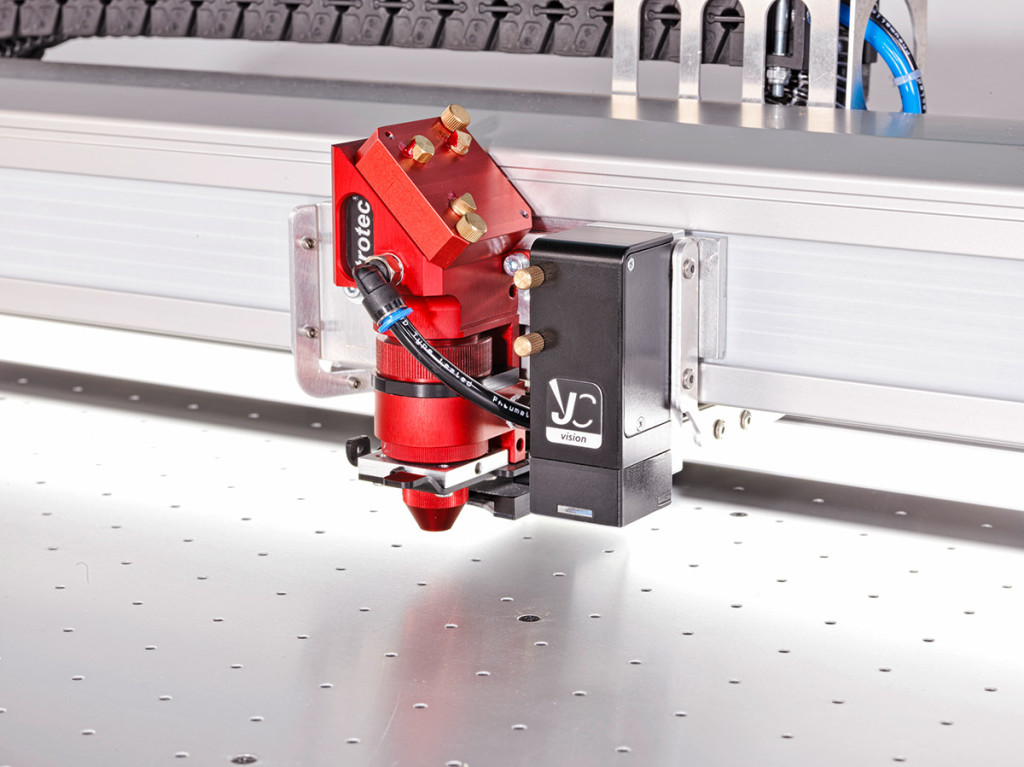

Perfect cutting of printed materials with the help of a camera system and detection of registration marks.

Live view of the product in Ruby software, for placing designs and jobs on the material according to the camera

Perfect cutting of printed materials assisted by a camera system and optical registration mark detection.

Get the perfect cutting result in a few easy steps JobControl® Cut is a fully integrated editor for processing and

Using the integrated touch screen, the laser can now be intuitively controlled directly from it. Access all your laser jobs

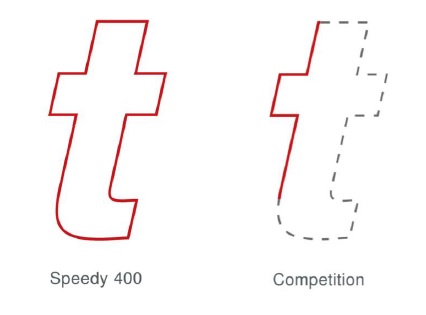

OptiMotionTM – record cutting speed Using OptiMotion™ technology, cutting speed and acceleration are calculated based on real-time geometry. This is

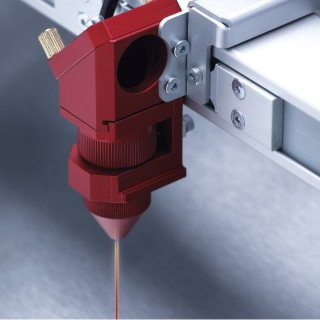

The laser pointer indicates exactly by a red dot where the beam of the laser machine will hit the material.

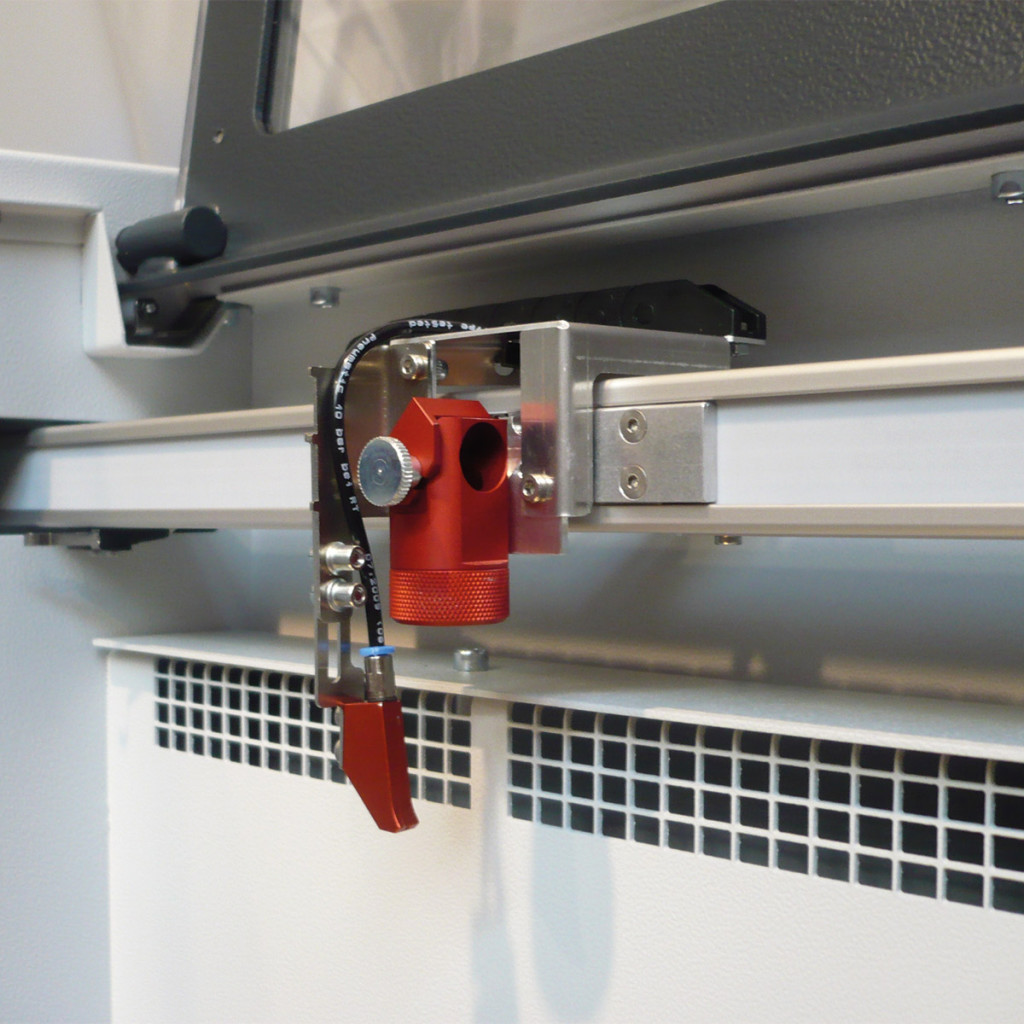

Improves the laser engraving on many materials while also protecting the optics of the laser engraving machine.

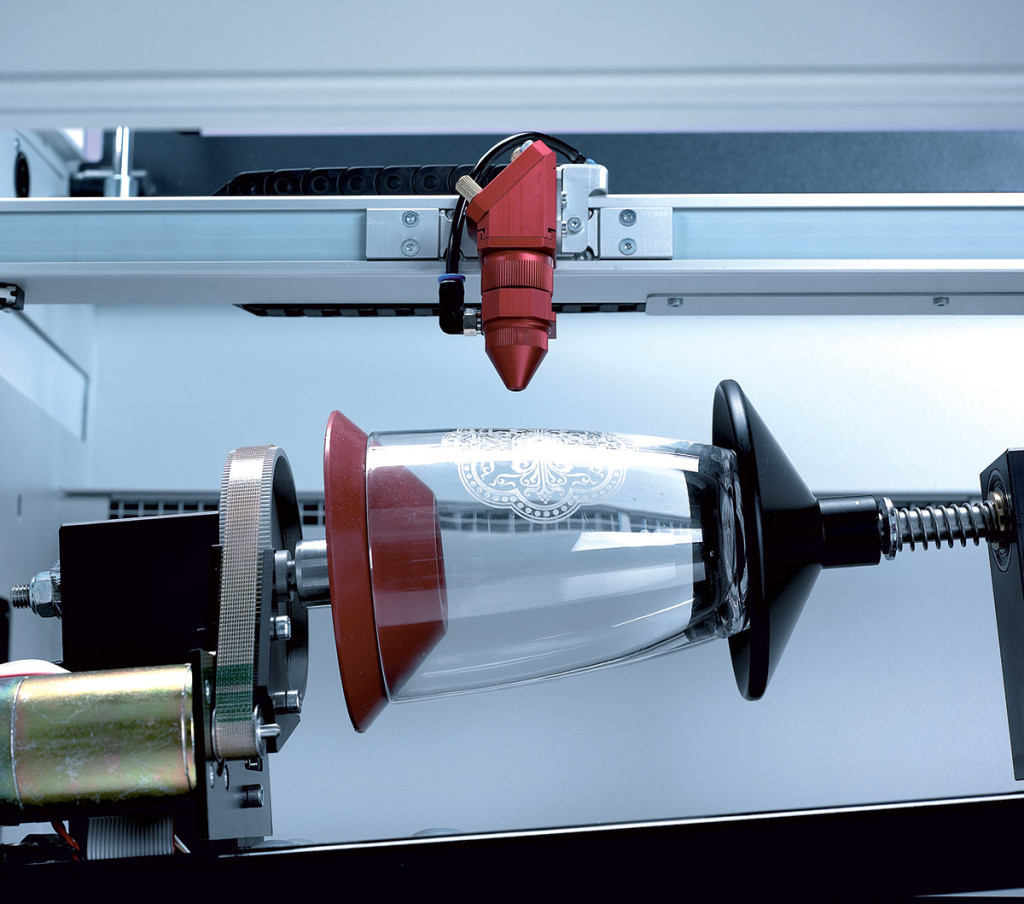

Is required for laser engraving round, cylindrical and conical objects, such as glasses or bottles. Simply insert it in the engraving compartment and attach.

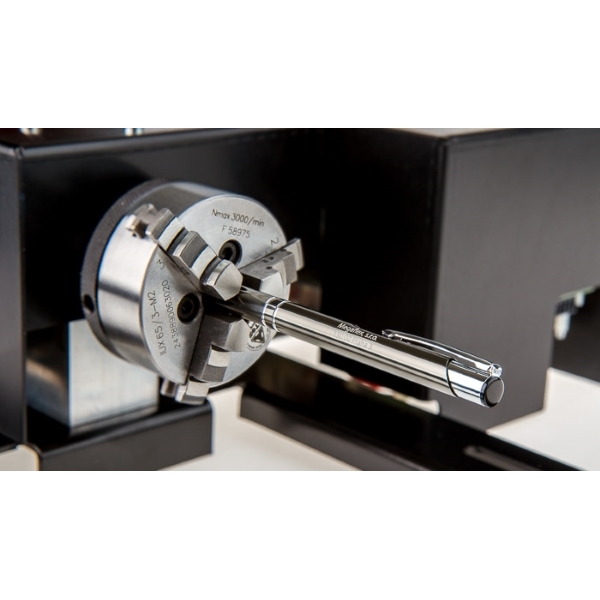

A universal self-centering chuck that is adapted for mounting on a standard Trotec rotator. The chuck allows not only direct clamping of objects, but also various adapters, holders, etc.

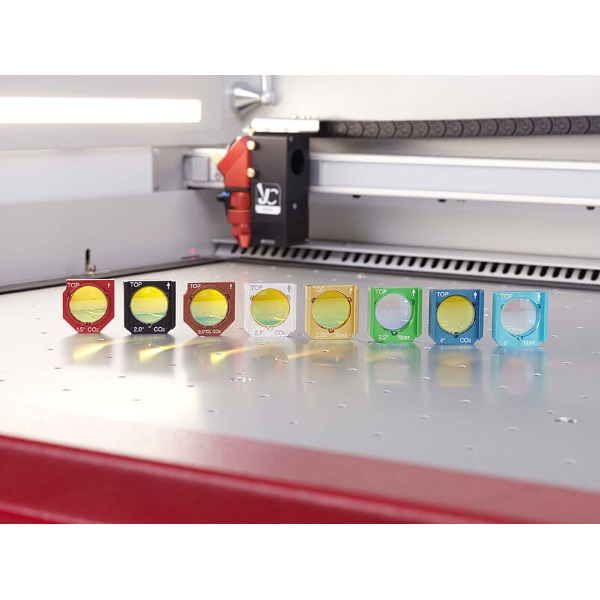

Find the right lens for achieving optimal results during laser engraving or laser cutting with Trotec laser machines.

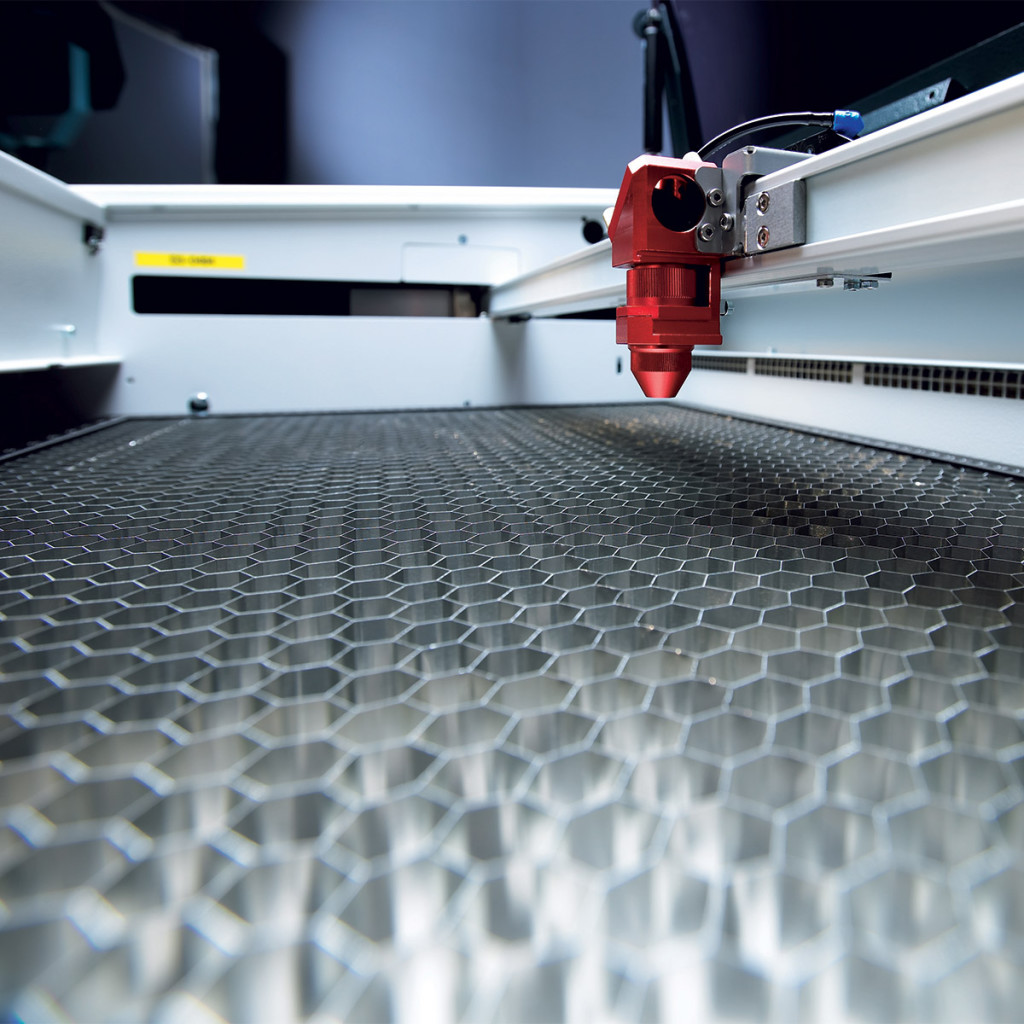

The cutting tables from Trotec reduce beam reflection and the disadvantages associated with it during laser cutting to a minimum.

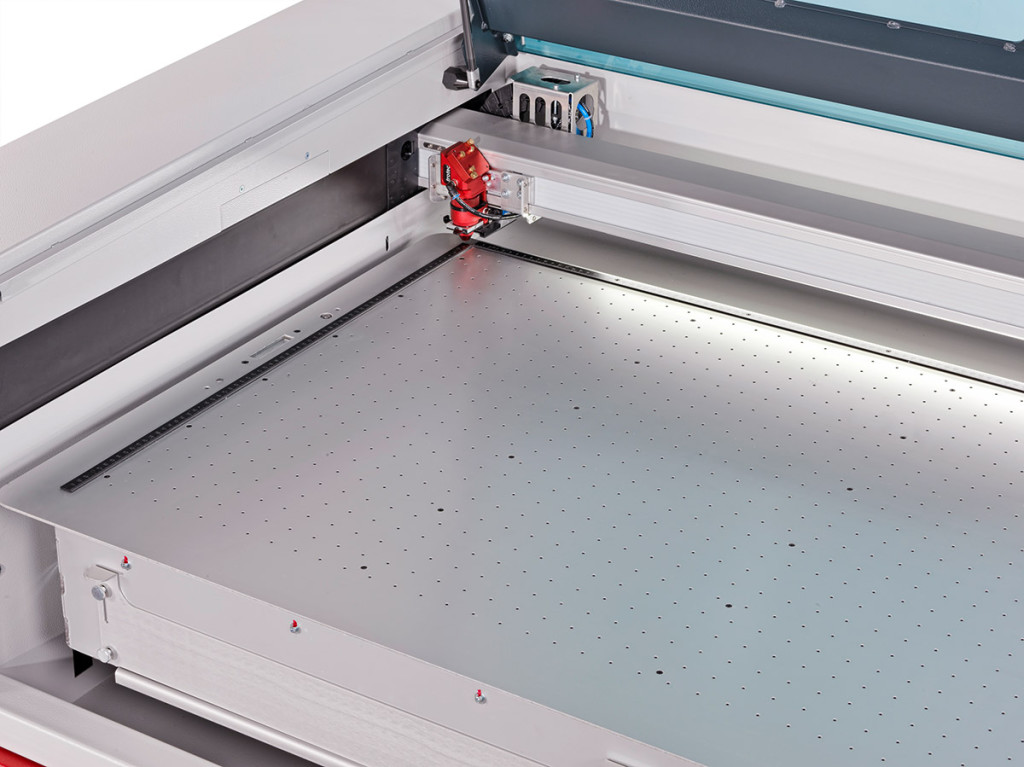

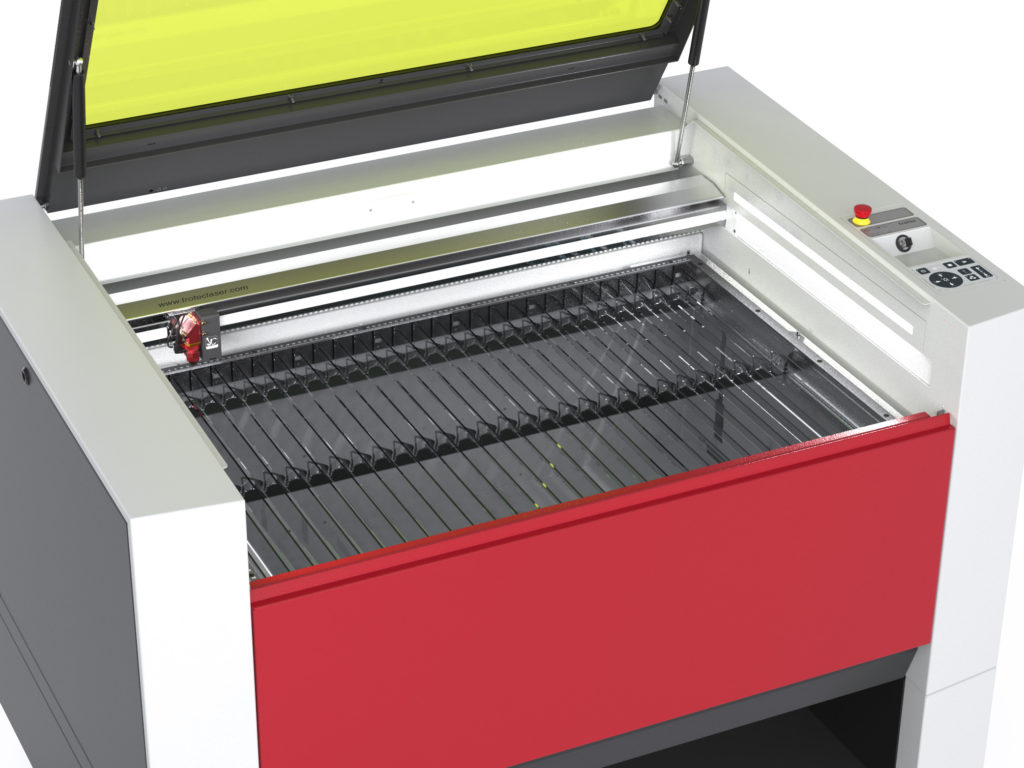

More tables – more possibilities For the SP500 Trotec has developed a unique, multifunctional table concept. Depending on the application

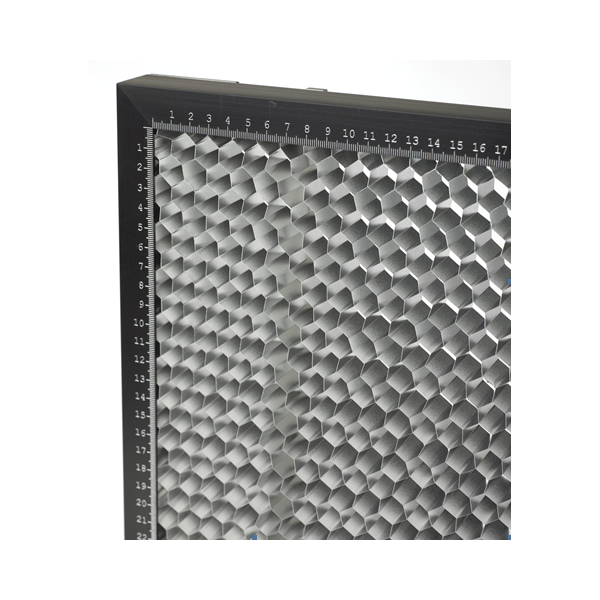

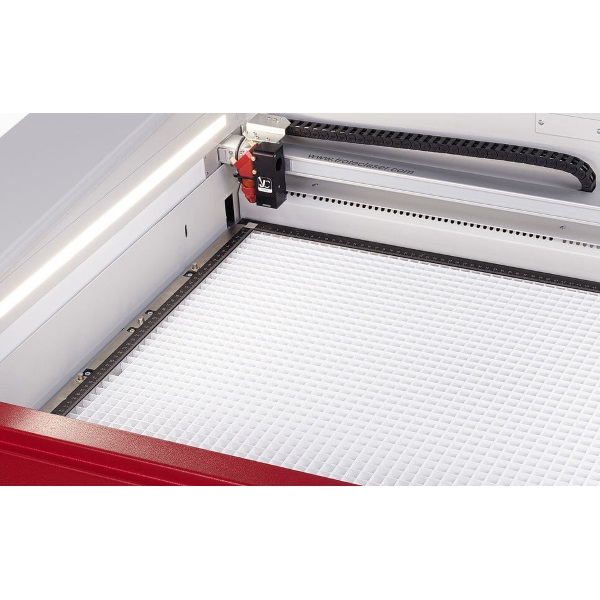

A Honeycomb cutting table can optionally be used when dividing materials. The use of a cutting table reduces back reflections from the work table, which can cause damage to the lower part of the material being cut.

The working table is ferro-magnetic over the entire surface. This means that you can simply use magnets to hold thin materials, such as paper, foils or films, in place.

The vacuum table holds the material in place on the work table and reduces the handling effort during fastening of the material.

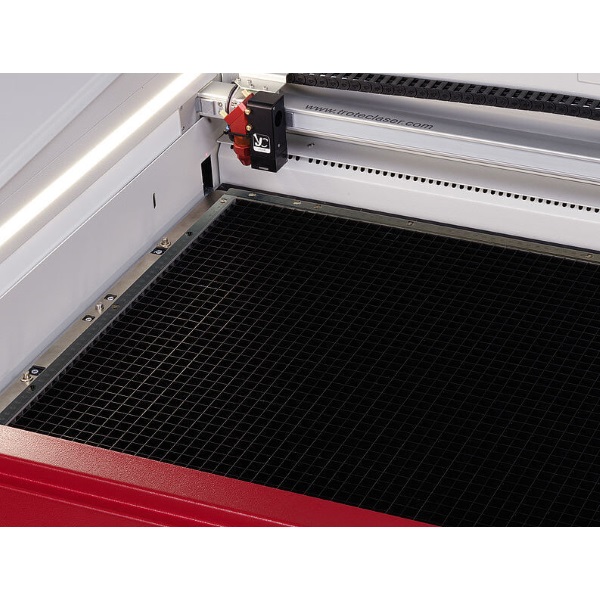

This robust universal cutting table features extremely stable combs and a long service life. This is particularly suitable for cutting

Universal cutting table for thin plexiglass cutting up to 8 mm thickness without reflection. As with the black aluminum cutting

The cutting table with aluminum slats is mainly used for cutting thicker materials (from 8mm thick) and for parts wider

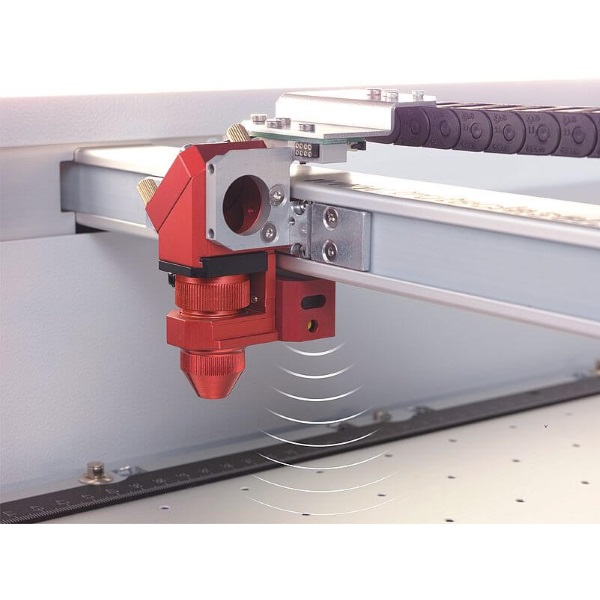

Sonar Technology provides a high level of accuracy when focusing on the material being laser processed, guaranteeing a higher quality.

Do not hesitate to contact us, our professional staff will be happy to advise you on anything about lasers.

You may use our smart filter in the catalog, too.

Mgr. Jiří Dušek

Head of the Laser department

website by dreamspace.cz