More possibilities for marking metals and plastics

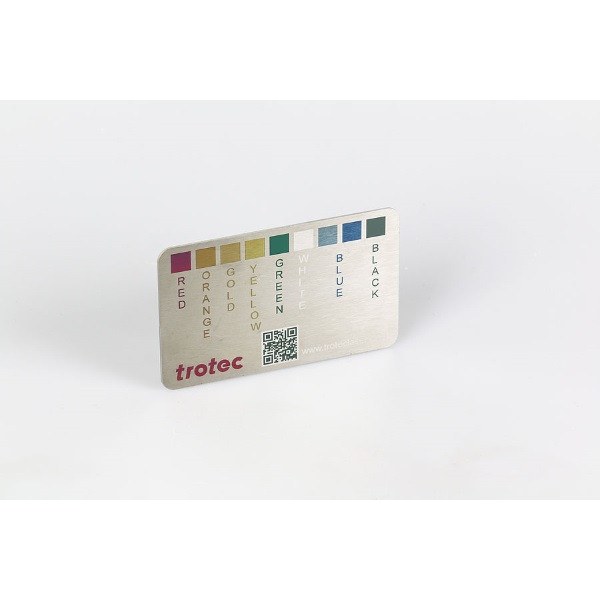

Expand your possibilities when marking metals and plastics. With the MOPA laser, you can also mark plastics higher-contrast and more legible results, mark (anodised) aluminum in black or create reproducible colours on steel. In addition, you can produce qualitatively equivalent markings with the MOPA laser often faster than with the conventional fiber laser.

With the MOPA laser, the pulse durations can be set to predefined values between 4 and 200 ns. The MOPA laser is one of the most flexible lasers on the market and can be used for many applications: With respect to pulse duration, it can simulate the properties of conventional fiber lasers (relatively long pulses) and those of classical solid state lasers (relatively short pulses) such as Nd:YAG or Nd:YVO4 (vanadate).

Advantages of MOPA laser

For short pulses and lower pulse energy, the material is e.g. heated less and the area of the heat affected zone is reduced. This results in more advantages and possibilities for laser marking metals and plastics:

- Less burning/melting in the edge area of metal engravings

- Less heat development during annealing markings on metal, which leads to a better corrosion behavior

- Controlled melting of plastics

- Less foaming with plastics

- More homogeneous and sometimes higher-contrast markings on some plastics

The advantages of the conventional fiber laser sources remain unchanged:

- maintenance-free

- long service life

- air-cooled

- economic purchase price