How does laser engraving of rubber work?

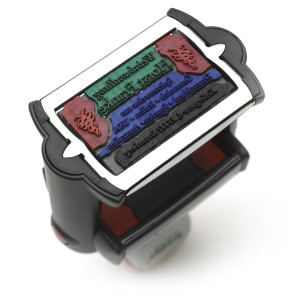

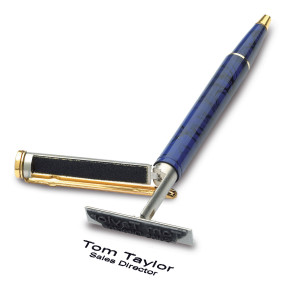

For laser engraving rubber stamps, the text must be mirrored and inverted. This is done automatically by Trotec JobControl. And using the JobCreator, type-setting for the rubber stamp is even easier.

What needs to be observed when engraving rubber stamps?

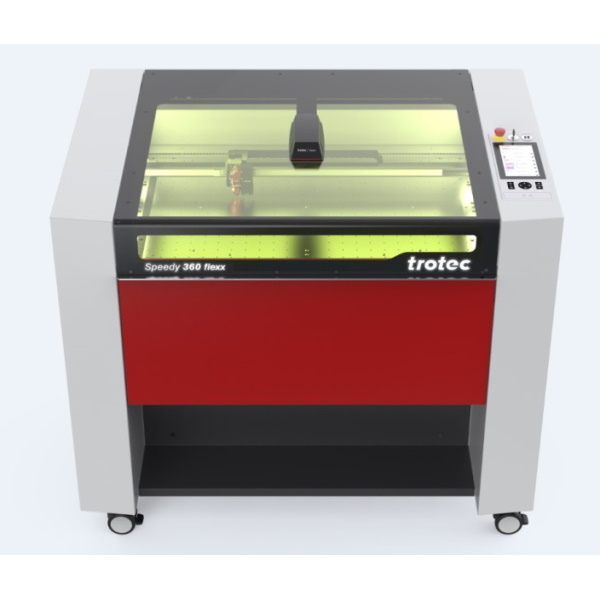

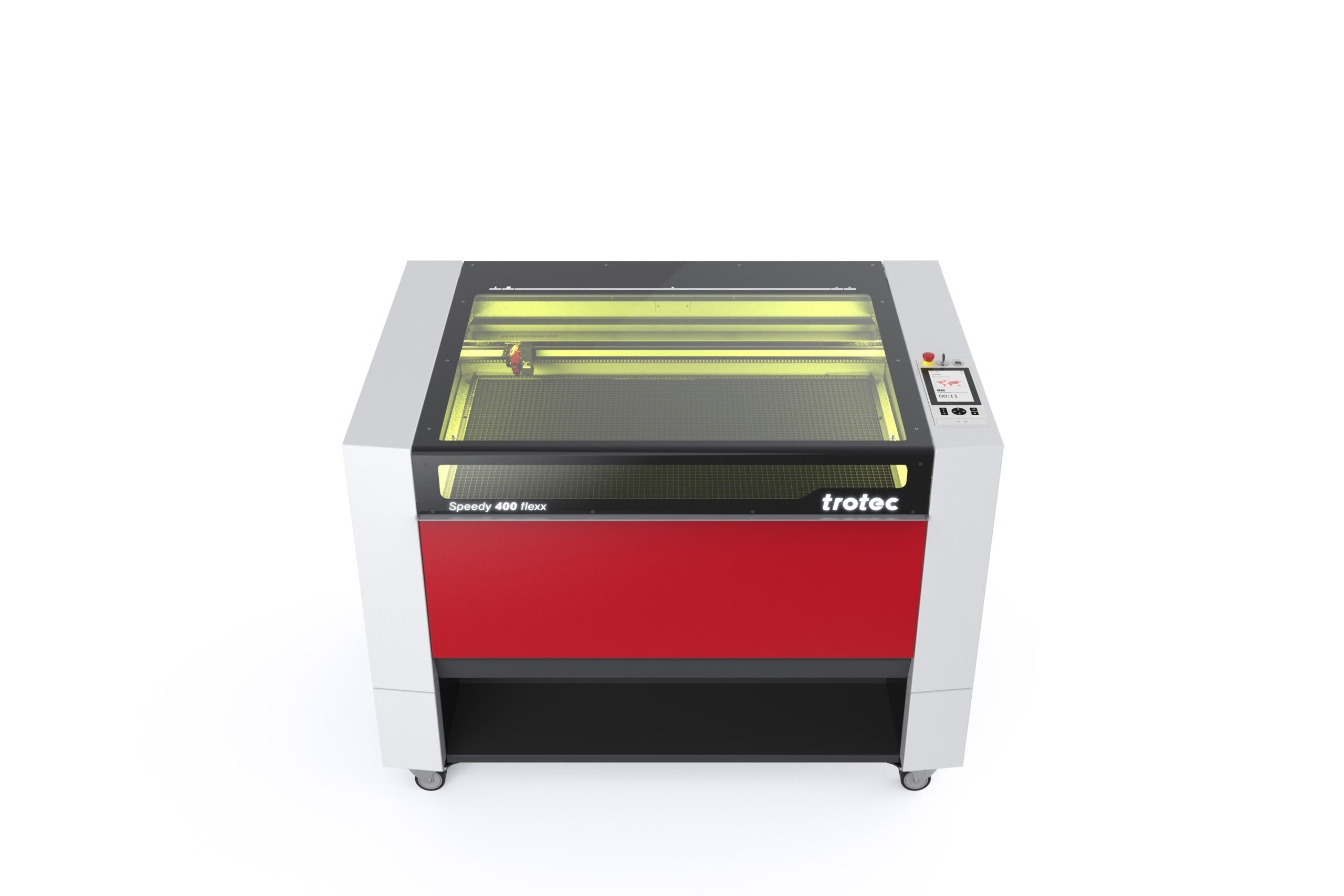

Laser engraving rubber for rubber stamps produces a great amount of dust. This dust must be extracted and filtered reliably and efficiently by an exhaust system. In addition, all dust-sensitive components, above all the lens, the mirrors, the electronics, motors and axes, must be protected from dust. Trotec laser systems have been perfectly designed for engraving rubber. Trotec’s InPack Technology ensures low-maintenance operation over many years.

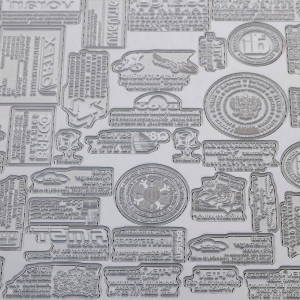

What types of laser rubber are available?

Trotec offers a wide range of rubbers for rubber stamp production. Odorless or ecological rubbers, oil-resistant stamp rubbers, or micro-porous foam.

Is it also possible to cut laser rubber with the laser?

Absolutely! The Trotec JobControl laser software offers various options for automatic cutting out: round, square, or optimized. On request, it is also possible to cut webs, in which case the cutting lines are interrupted at defined points.

What other materials can I work on?

A CO2-laser can be used for engraving or etching a wide range of other materials, such as wood, glass, rubber, acrylic and plexiglass, plastics, leather, paper, textiles or foams.