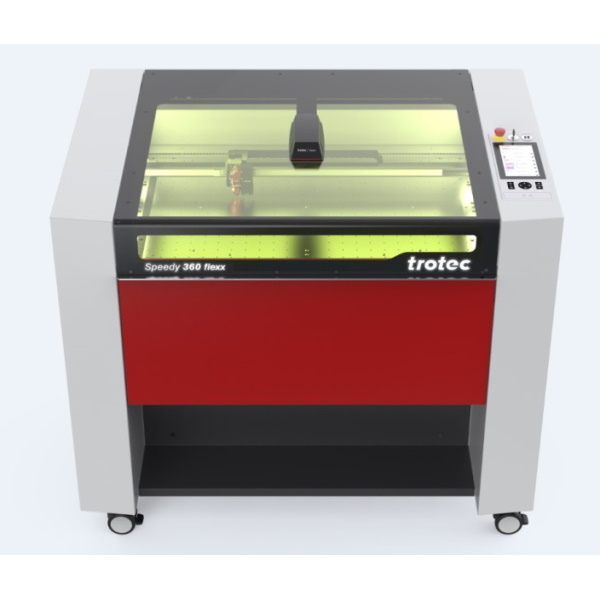

The benefits of a laser cutting machine: Faster than a cutting plotter, more precise than punching dies, and more economical for small series up to 1,000 pieces.

How does laser cutting of foils and films work?

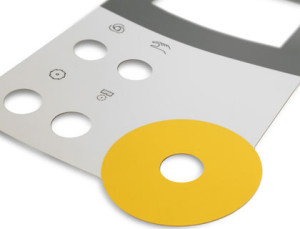

The controlled fusing of the material ensures clean cutting edges without any soiling. The laser offers many advantages when working with multilayer films: Several layers, such as backing, adhesive and top film, can be cut in one work step. Depending on the layer structure and the strength of the film, up to 10 layers can be cut in the composite material.

Do I have to fixate the material on the working surface?

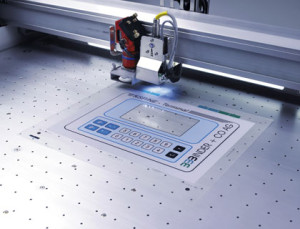

No, not manually. For optimal cutting results, we recommend the use of a vacuum table. This ensures that thin or wavy materials are positioned flat on the work table, as for laser cutting. No pressure is exerted on the material during laser cutting of foils and films; clamping or any other type of fixation is therefore not required. This saves time and money during the preparation of the material, and last but not least, prevents crushing of the material. All these advantages combined make the laser the perfect machine for cutting foils and films.

Why will I work faster with the laser than with a cutting plotter?

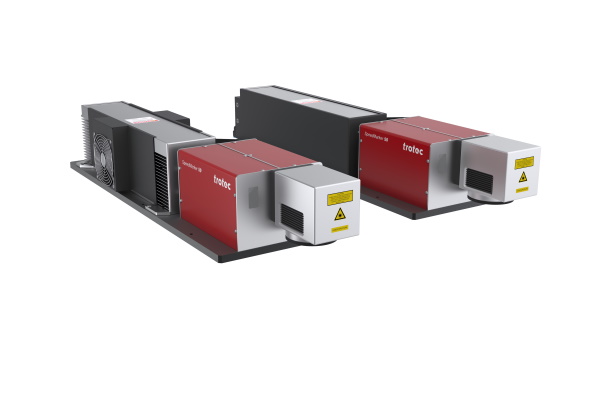

Precisely matched axis drives and an innovative control system ensure precise and fast laser cutting with Trotec systems. Unlike in cutting plotters, there is no material resistance when lasers are used. As a result, laser cutting is faster. Another plus: The laser beam does not need to be lifted or rotated as a knife. Trotec laser systems make optimal use of this advantage in speed and detail, in particular when working on delicate geometries

Do I require special accessories for accurate laser cutting of foils and films?

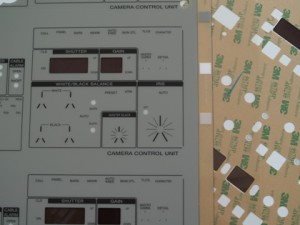

A camera system is the ideal partner when you wish to process printed products. i-cut® allows for perfect contour cutting of printed materials. Even flexible materials, like banners and flags, are thus cut absolutely accurately. Time-consuming positioning falls away, distortions in the impression are detected, and the cutting path is adapted dynamically. By combining the optical registration mark detection system with a Trotec laser, you can save up to 30% in process costs. There are no costs for the manufacture, maintenance and storage of the cutting dies. In addition, absolutely flexible work is ensured and it is possible to respond to any changes in the design in the shortest possible time.

Material overview

| Material | Abbreviation | Trade names |

| Polyester | PES | Thermolite®, Polarguard® |

| Polyethylene terephthalate | PET | Mylar® |

| Polyimide | PI | Kapton® |

| Polycarbonate | PC | Lexan®, Makrolon® |