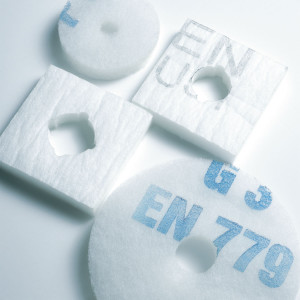

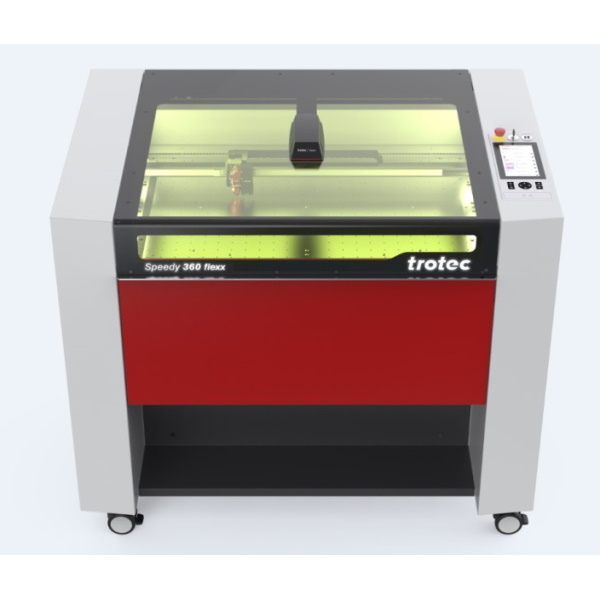

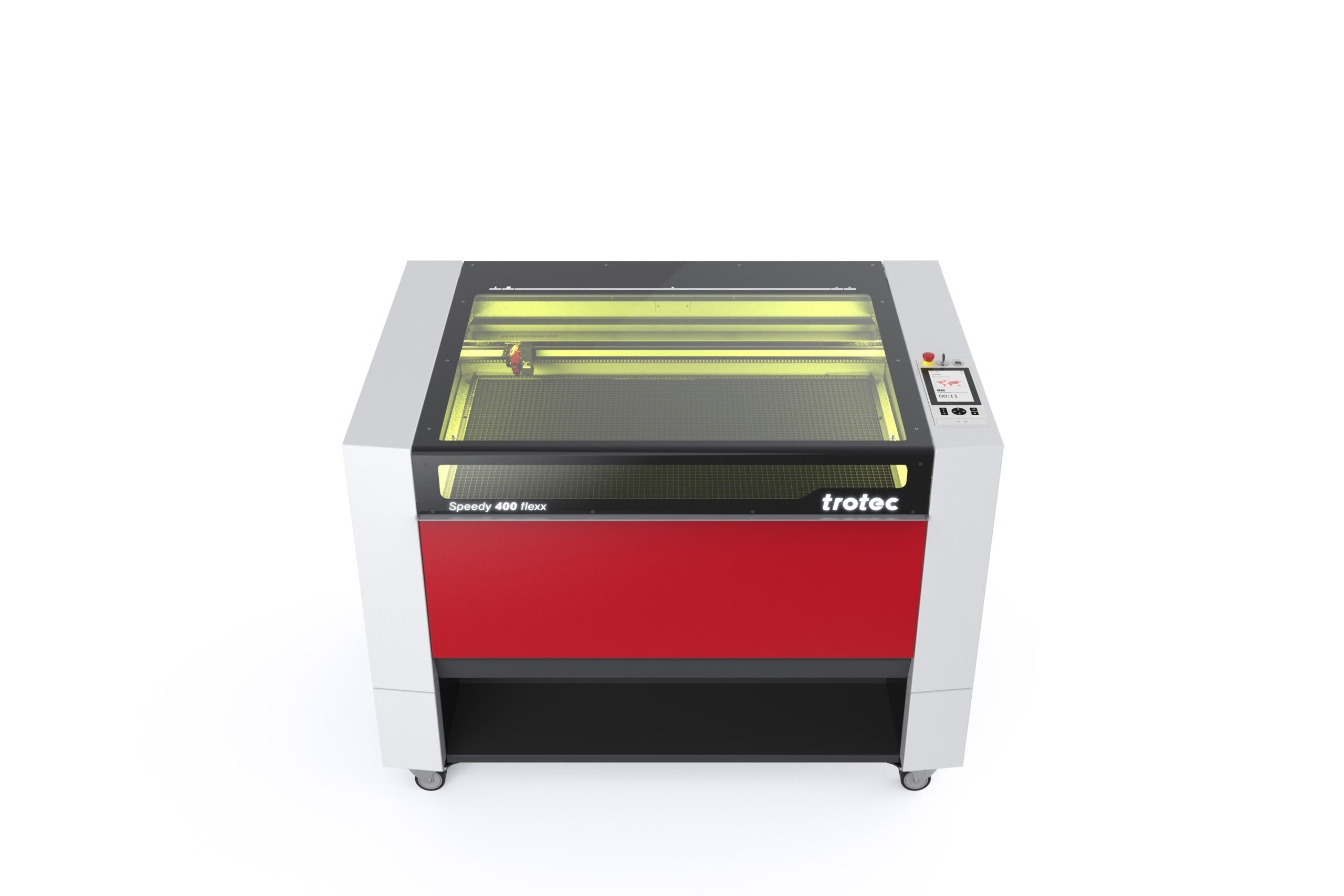

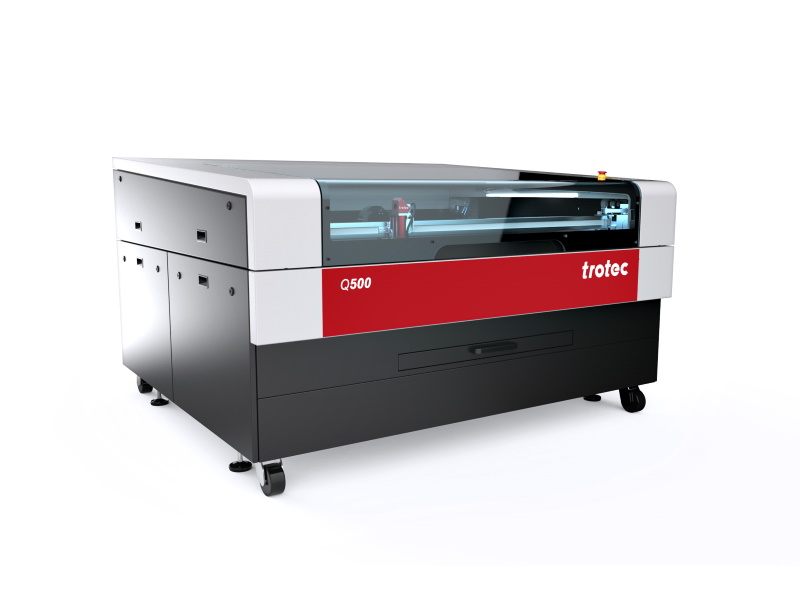

What is special about laser cutting of foam?

The laser is a highly flexible tool: Everything is possible, from prototype construction through to series production. You can work directly from the design program, which is very important especially in the area of rapid prototyping. Compared to the complex water jet cutting process, the laser is significantly faster, more flexible and more efficient. Foam cutting with a laser machine will produce cleanly fused and sealed edges.

Do I have to fixate the material on the working surface?

No. The laser does not exert any pressure on the foam during the process, clamping or any other type of fixation is therefore not required. Simply insert the workpiece and start the laser process. This saves time and money during the preparation of the material.