With the marking lasers of the U series, you can quickly and easily mark individual pieces as well as small and medium batches. Thanks to the maintenance-free fiber laser source, plastics can be recolored and metals permanently marked directly – without the use of sprays or pastes. U-series products are equipped with high-quality optical elements and scanners – both components ensure precisely marked parts.

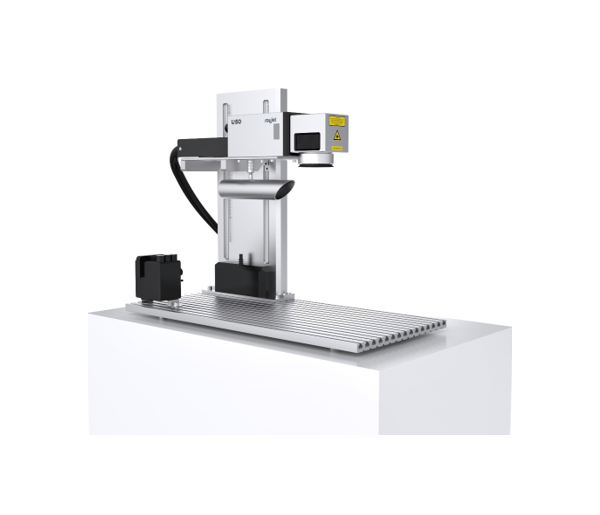

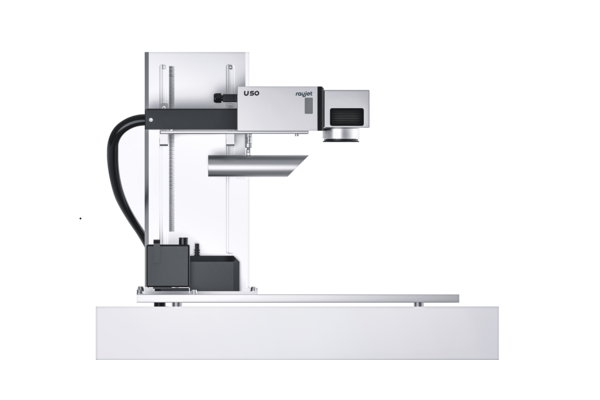

The U50 – an open class 4 laser system – can be positioned anywhere to mark larger or bulky components.

Process dynamic data at high speed

UMark software allows you to mark your information on an object in no time. This allows you to generate codes, import data files or graphics, and create texts. This software also has a material database so you can use the correct parameters as quickly as possible. You can also add your own parameters to this database.

Save time with Bordermarking

A special feature of the U series is the bordermarking capability – this allows the surface to be marked to be projected onto, or even contoured onto, a part at any time. Positioning is done in real time and can be corrected with one click of the mouse if needed.

Best engraving quality thanks to high quality optics

High-quality lenses and an excellent laser spot guarantee a perfect application result for your marking. This enables precise marking of even the smallest details. Features such as polishing and deep engraving ensure legibility even on difficult materials.

Independent and flexible via Ethernet

Thanks to the newly integrated interface, the laser can be controlled using any Windows computer. This means that you are no longer tied to the functionality of an industrial computer. Simply plug and laser – you’ll be surprised how much time you’ll save!