Optimized workspace – productivity.

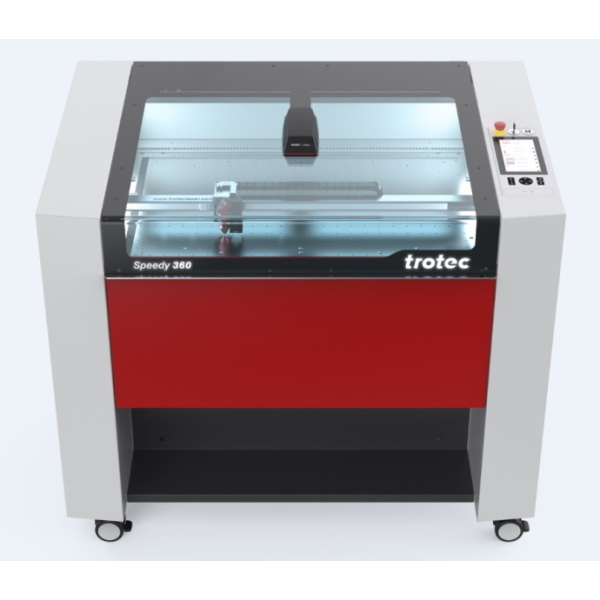

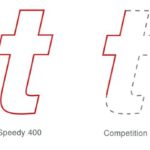

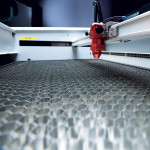

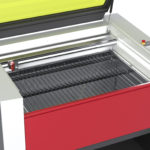

With a work surface of 813 x 508 mm, the Speedy 360 allows you to use standardized material sizes, allowing you to save time and money on material preparation, use more blanks according to the workbench and take advantage of the full work surface. In addition, with a maximum engraving speed of 355 cm/s, the Speedy 360 is designed to increase production capacity. Contains complete new electronics.

The widest range of options – flexibility.

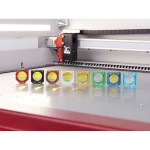

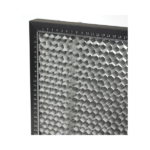

The Speedy 360 can be upgraded to the Speedy 360 flexx version at any time according to your needs. The patented flexx technology enables endless application possibilities using one laser machine in one work step. By offering different options, such as a multifunctional table concept, different lenses or laser power upgrades, the Speedy 360 is tailored to your individual requirements.

Run On Ruby

The Speedy 360 can now be operated independently, it connects to a computer network via Ethernet, and a connection to a PC via USB is no longer necessary. Possibility of wireless connection to a computer network.

With the new integrated touch screen, the laser can now be intuitively controlled directly from it. Access all your laser jobs right on the machine and run them straight away.

Now you can easily access your laser remotely, even directly from your smartphone or tablet.

Simplify your daily work – usability.

Setting up your jobs for the laser is very simple and easy. Trotec Ruby software is equipped with many useful functions for engraving and cutting. Inserting and removing even heavy and bulky parts is convenient thanks to easy access from the front of the laser and the front cover can be tilted up to 180°. LED lighting ensures even illumination of the work surface and the compact design makes the Speedy 360 a versatile tool, especially when space is a problem.