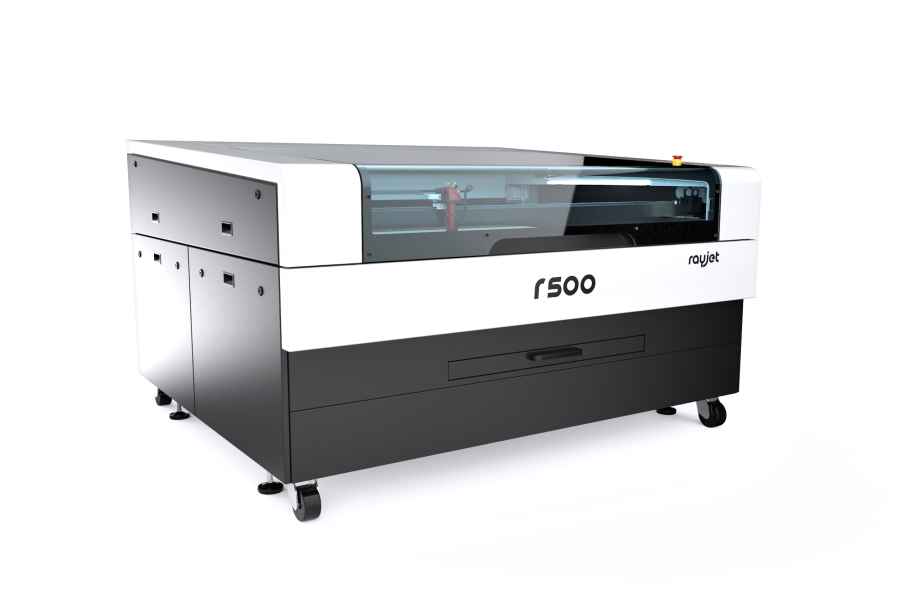

The R500 provides a large format processing area of 1300mm x 900mm combined with 120W CO2 laser power, making it an affordable package with plenty of processing options. The machine uses servo motors for the X and Y axis, providing a cost-effective, reliable solution. It also includes a manual Z-axis adjustable on the laser head. The machines are equipped as standard with a suitable water cooler, which is located next to the laser system. This circulates water through the laser and maintains a target coolant temperature of 25℃, resulting in very reliable and stable performance.

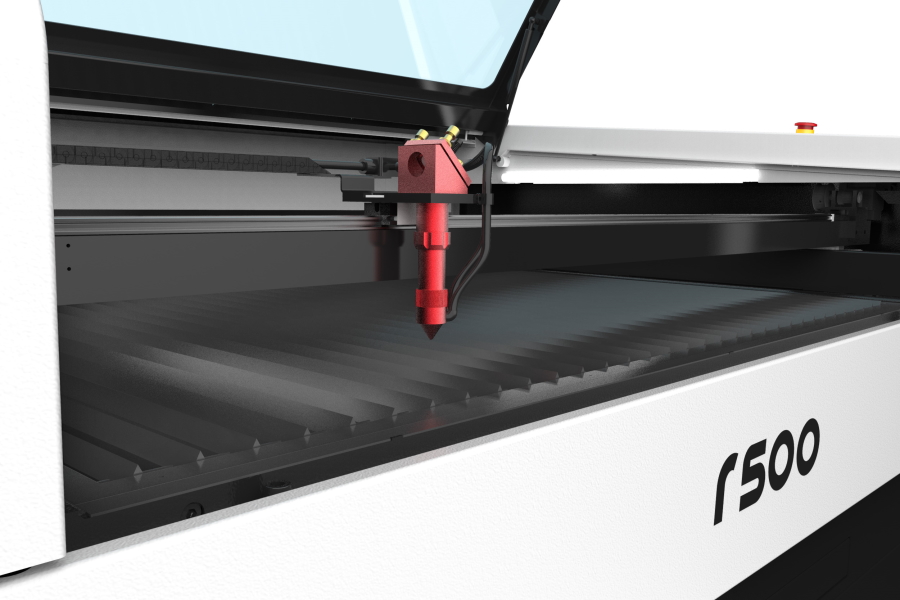

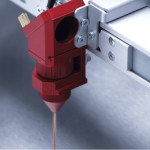

Adjustable Air assist – provides a combination of optics protection and at the same time significantly reduces the risk of flame. The flow of compressed air can be easily adjusted with a valve directly at the laser head to prevent movement of fine material during laser processing.

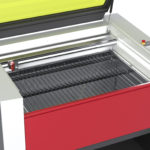

The R500 can be equipped with any of the available cutting tables to process a wide range of material options. You can choose from an aluminum table with slats or an aluminum cutting grid.

Great interior view and ergonomic design

The extra wide view into the laser work area makes the R500 a pleasure to work with. It allows you to monitor the progress of your work at a glance, even from a distance. The ergonomic and open design of the R500 ensures efficient operation. The top cover has been designed so that users can easily insert large format sheets of material directly onto the laser work surface.

Austrian engineering and quality standards

The R500 is developed by Trotec. We follow strict production procedures and European production standards. The R500 is equipped with high quality components: Trotec laser driver, CeramiCore® laser sources, industrial quality sources and linear guides. The robust mechanical and reliable electronic design is proven on thousands of Trotec laser machines.

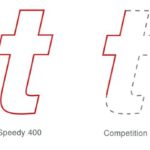

Powerful control software

Rayjet Manager is based on Trotec’s top software concept. With Rayjet Manager software and Rayjet Commander print driver, files are sent from all graphics and CAD programs directly to the laser cutter, compatibility guaranteed. With the software and controller developed by Trotec, the motion and laser processes are perfectly aligned to maximize system performance. Our “one-click setup” will have you up and running in minutes. Thanks to the built-in materials database, you will be efficient from day one.