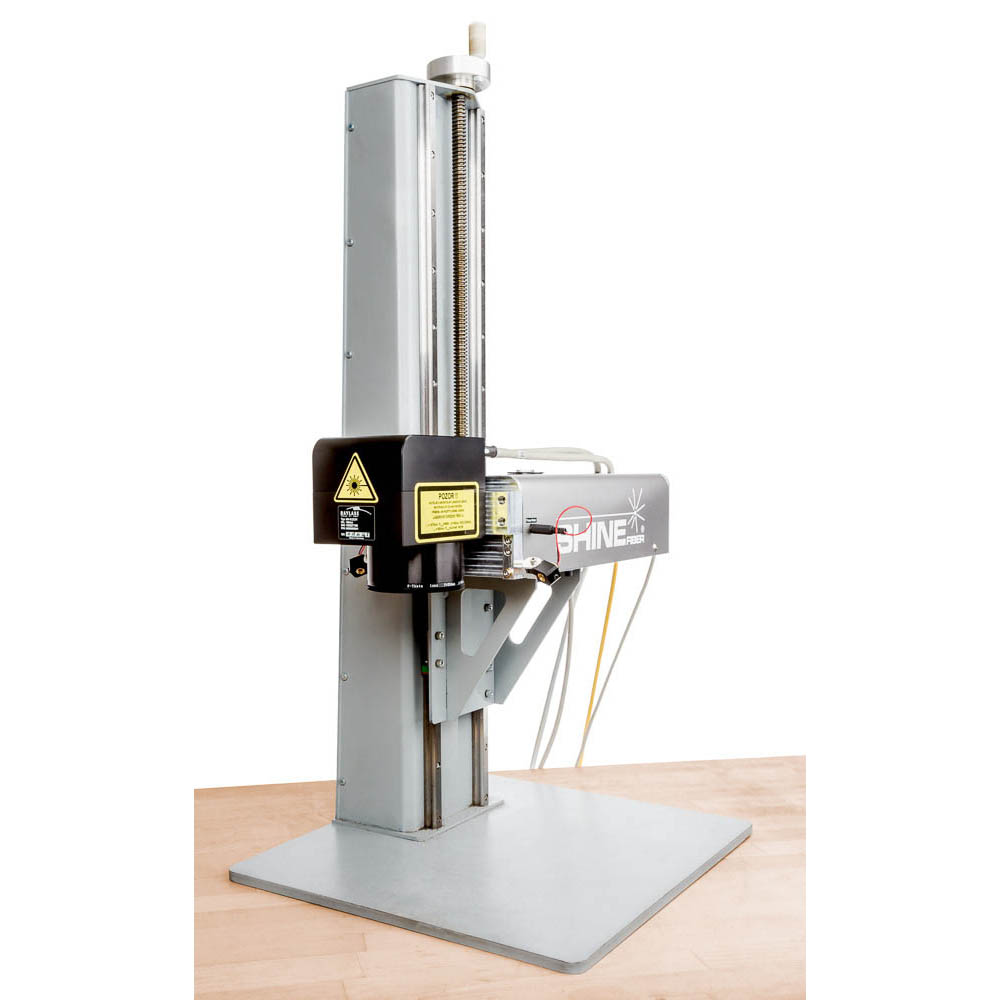

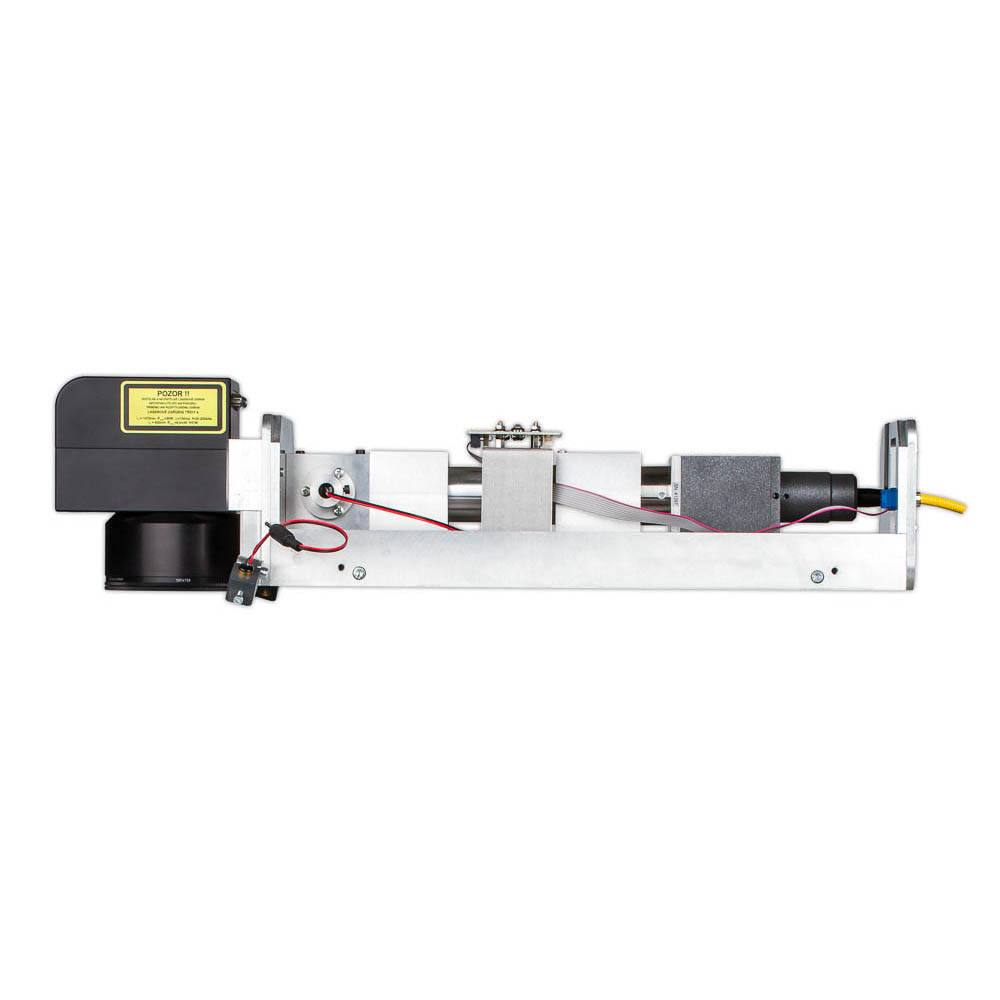

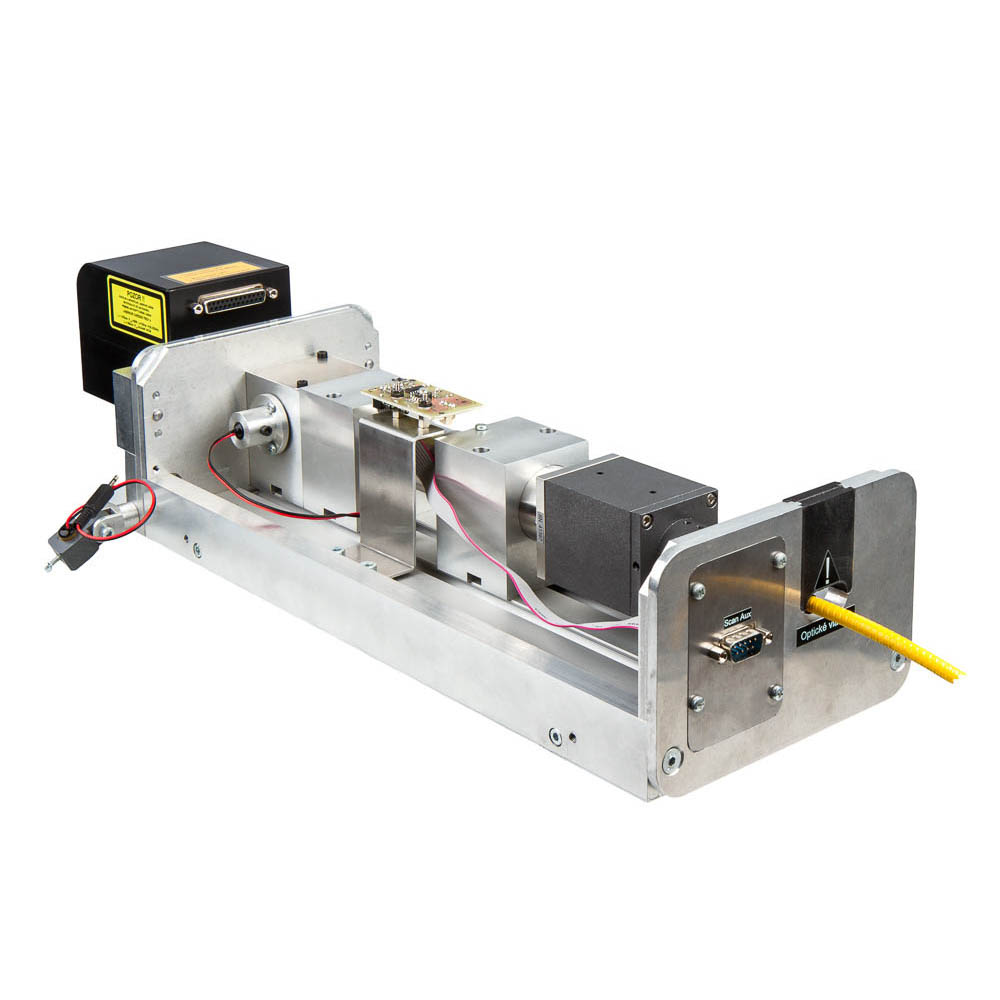

SHINE Fiber II is a modern, compact laser marking and engraving system ideal for integration into production lines or individual workstations. Laser is suitable for permanent marking of metals and plastics, engraving in places inaccessible to ordinary tools, deep engraving and so on. OEM products (Original Equipment Manufacture) without protective covers is a laser class 4!

System for industrial marking and labeling of metals and plastics, providing the latest fiber laser. Integrated PC control program SCAPS Light 2D (also available for the 3D version), standard lens with a focal length of 160 mm and max. surface of 110 x 110 mm (the next version of the 100 / 60×60 mm, 254 / 180×180 mm or 420 / 280×280 mm) laser YLP 10 – 100W, safety category 4 as OEM, Miniscan scanhead series. The device is ideal for industrial description and can be easily integrated into new or existing production lines. It can be buil-in into a stand-alone workstation, for example with Megaflex SHINE Workstation (protection class 1).

Software MEGAFLEX-SCAPS

Megaflex-Shine is controlled by a universal software Megaflex-SCAPS (MS Windows ™), whose transparent and intuitive structure allows you easy adjustment of all parameters of marking. Megaflex-SCAPS is a WYSIWYG vector editor, which is very easy to operate, while providing maximum flexibility and is suitable for even the most demanding industrial applications:

– control of all laser parameters: power, pulse frequency and speed of marking …

– identifies the main vector and bitmap graphics formats (* .plt, * .dxf, * .dwg, * .cmx, * .tif, * .pcx, * .bmp, svg, emf, MCL, twain, ai etc.)

– editing of texts (laser and Windows ™ True-Type fonts), resize, rotate, skew, perspective, shading etc.

– drawing of basic geometric objects (point, line, polygon, rectangle, ellipse …), logos (import / export)

– easy to work with barcodes and data matrix (2D bar codes, data matrix)

– automatic generation of barcode or 2D code on a database or input data

– automatically inserting the current date and time

– automatic counter of products

– “Multi-object marking” – option to set custom laser parameters for each object (marking / cutting in one motif)

– programming and scripting – change labeled theme based on input data (generic algorithm)

– optimization of marking speed – preview editor

– complete documentation

– create your own user management applications (Visual Basic, C ++)

– ensure safe operation (emergencies and alarm monitoring)

– the price includes 12 months free upgrade to a higher version of SW

Excellent price / performance ratio

– up to 100,000 hours extremely long life of the laser source

– suitable for integration into production lines and independent solutions

– made in Czech Republic

– no wearing parts

– no consumables such as. ink etc.

– maintenance free – regularly cleaned only output laser lens

– equipment laser safety class 4